The maintenance of the shock absorbers in good condition is essential for operating safety of automotive vehicles and improves the driving comfort of the vehicle.

The vibrations occurring in vehicle wheels and body are eliminated or significantly reduced by shock absorbing elements. Their task consists in damping of vibrations generated in the vehicles suspension system. The damping consists in the reduction of magnitude of the vehicle wheel and body (vibration amplitude) and in the reduction of their duration. The hydraulic shock absorber is the typical and commonly used shock absorbing element. The correct functioning of the suspension system is essential increasing the adhesion of the vehicle to the road surface, because it increases the duration of vehicle contact with the ground when travelling across uneven surface. The service life of the vehicle as well as functioning reliability of other subsystems, passengers comfort and the condition of transported goods is also significantly affected. Therefore, the determination of its condition is crucial for correct vehicle operation.

It is ironic that often when a vehicle’s braking system is inspected, it is not done in line with the testing of the wheel’s traction.

No matter how effective a vehicle’s brakes are, it is useless if the wheels cannot effectively grip the road.

An ineffective wheel will lead to extended stopping distances and inefficient driver assistance systems, such as ABS and ESP. In turn, a wheel can become counter-productive, bouncing will persist and its shock absorber will be damaged.

Unfortunately, most inspections are only conducted visually and therefore 50% of wheels are not properly assessed. This will continue to be a common problem, unless shock absorb testing becomes an integral part of the inspection process.

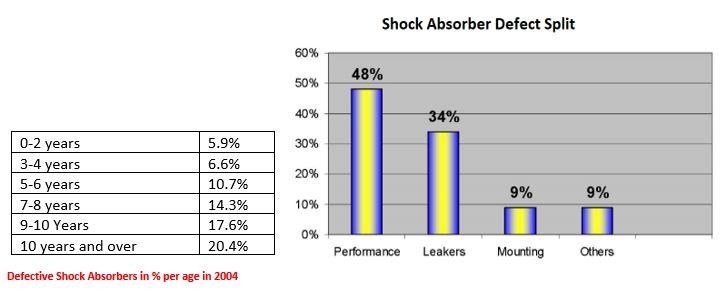

Shock absorbers have a limited life span. On average 10% will fail by 5 years as indicated in the table and graph below. It is therefore critical to conduct shock absorber tests in line with all visual inspections.

The suspension system plays an important role in the safety drivability of a vehicle. To maintain the system in a safe condition you need to know the shock absorber performance during the life of the vehicle, the brake system has an objective check method and validation criteria, regulated by most authorities that must be met for approval of the vehicle in order to determine the system effectiveness, this is also reinforced in some domains by a regular periodic inspection.t

To test the suspension, there are to methods , a vibrating platform test bench or a portable electronic meter both use similar mathematical methods for examination and assessment, however the price and flexibility of the vibrating plate makes it less attractive, additionally it suffers from variances in the profile and inflation of the tyre.

Two main measurement systems exist

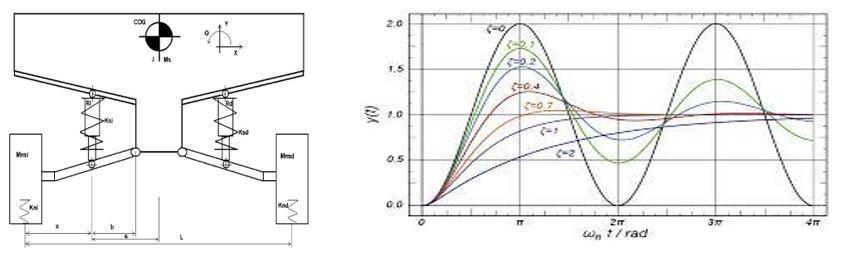

The procedure is to determine the damping coefficient of the suspension system, the damping coefficient, being defined as the quotient of system damping and critical damping (damping with no oscillating movement)

To get the correct measurement outcome you must excite the system with sufficient energy over a wide frequency range. This is more commonly known as the “EUSAMA” method, however, to get the best results that are repeatable

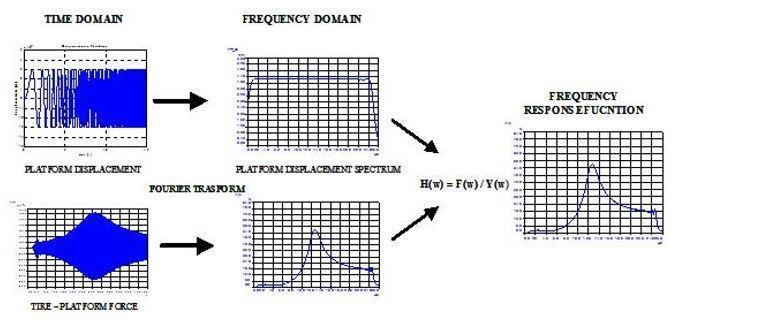

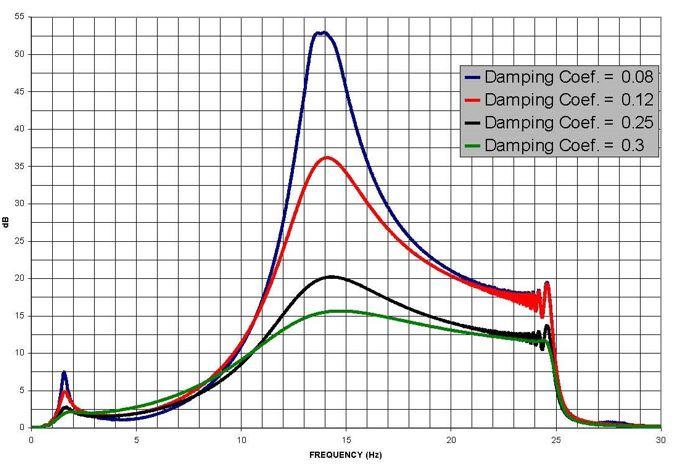

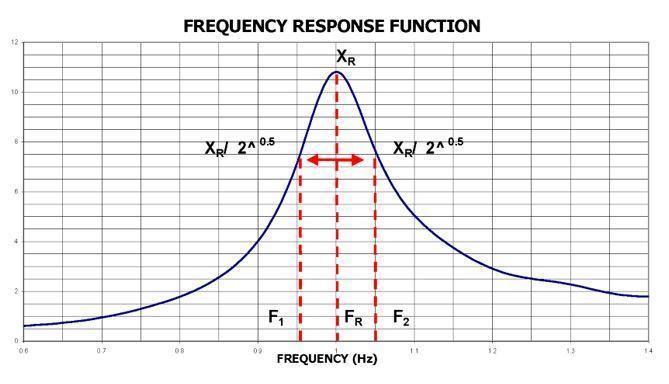

The Excitation starting frequency should be decreased to 4 Hz, the excitation amplitude should be greater than 25mm, the method ramps the excitation frequency at a displacement of 25mm from 4hz up to 30Hz at a rate of 0.1 Hz/s which allows sufficient dwell time to adequately measure the response function, an elaborate signal processing system is required to determine the response function. This system measures the tire-platform force signal and is expressed in the frequency domain through a Fourier Transform in order to obtain the Frequency Response Function (FRF).

This value can be estimated from the shape of the Resonance Peak on the FRF the Frequencies F1 & F2 can be determined by taking the frequencies at half the power amplitude of the resonant peak.

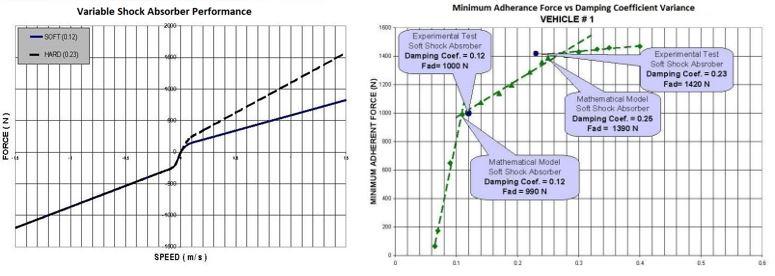

From the equations the Minimum adherance force measured between tire and road (time domain) is called “Fad ” and the Damping coefficient measured by the method above indicated called x (zeta).

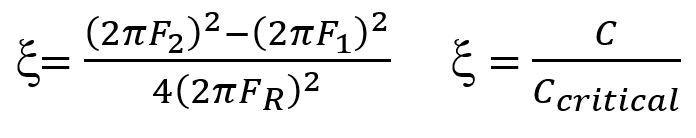

By plotting the ratios of Fad against x there are 3 significantly different areas can be observed:

By changing the vehicle or using a different vehicle configuration, the inflection point between “Area#1” to“Area#2” does not significantly change, this allows us to determine a minimum damping coefficient below which, suspension system performance decreases significantly and driving safety could be seriously affected.

For the sake of this discussion it can be referred to as: “damping coefficient limit” (xlim).

It is the damping coefficient value that produces the change from Area#1 to Area#2.

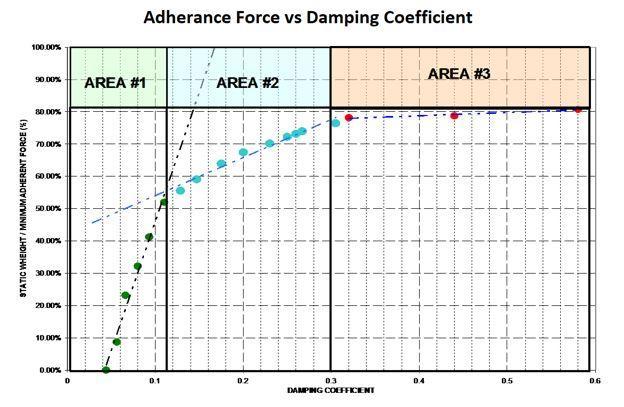

If you do a statistical analysis on a number of tests you can look at the influence of different design parameters

Several experiments were conducted to verify these were conducted using a prototype.

Model based results have been verified by experimental tests a prototype of vibrating platform and a vehicle equipped with variable shock absorbers.

Suspension system status can be achieved by either a portable electronic meter or a vibrating plate, characterizing dynamic behaviour of suspension system in vibrating test bench is sufficient to excite sprung mass resonance.

Using FRF it is possible to determine the damping coefficient of the shock absorber. A Damping Coefficient limit as a validation criterion has been established by both calculation and experimental means, below which the dynamic behaviour of the vehicle demonstrates significant loss of performance.

This article was featured in AAAA magazine (Australian Automotive Aftermarket Association) September 2021.

Keep your workshop and equipment updated!

Subscribe to our newsletter for exclusive sales, discounts, and the latest news.

Sign up today!