IN THIS ARTICLE: Several factors affect how your vehicle’s brakes work. These include the speed and weight of your vehicle, brake adjustment and anti-lock braking systems.

Several factors affect how your vehicle’s brakes work. These include the speed and weight of your vehicle, brake adjustment and anti-lock braking systems.

Increasing how much weight your vehicle carries or how fast you drive increases the effort required by your brake system. As it increases, the brakes must do more work. In an air brake system, this means greater brake application pressure will be needed to meet the higher demand.

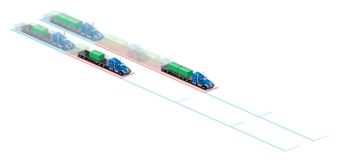

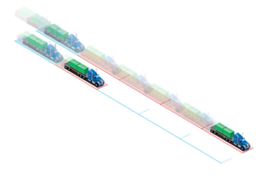

Double vehicle weight – Double stopping distance.

Brake systems are designed for use on vehicles that are loaded within their rated capacity (GVM). Exceeding the GVM of a vehicle places abnormal demands on its brake system.

Vehicle weight affects the brake system in the following ways:

As vehicle speed increases, the stopping distance increases at a rate that is greater than the change in speed. For example, when speed is doubled, the stopping distance increases by four times.

Double vehicle speed – Quadruple your stopping distance (the square of the speed).

Note: If you double your vehicle weight and double your speed, your stopping distance increases by eight times.

There are many factors that affect a vehicle’s stopping distance. Stopping distance can be calculated based on time and speed. A split-second delay in brake application and release ranging up to one-half second is present in all air brake systems. This delay must be considered when determining suitable following distances and appropriate action during vehicle stops.

Brakes convert the energy of a moving vehicle into heat. The frequency and type of brake use determines how much heat is created. When brakes are used repeatedly – such as when travelling down a long or steep hill or driving in stop-and-go traffic – or when severe braking takes place, the operating temperature of the brakes can become higher than normal. In some cases, brake temperatures can become so severe they cause damage to brake components.

Driving habits affect the amount of heat that develops in the brakes. Good driving habits include anticipating road conditions and leaving enough time to stop. In particular, keeping a safe distance behind other vehicles reduces the incidence of harsh brake use and excessive heat build-up in the brakes.

Some vehicles use engine brakes, retarders or auxiliary brakes – fitted onto drive lines that use engine compression, hydraulic or electric means – to slow it and assist in avoiding excessive brake temperature.

As brake components heat up, you may experience a reduction in their effectiveness and find that you need to press harder on the brake pedal to develop enough brake force. This is known as brake fade, and it is more noticeable on some vehicles than others.

In extreme cases, such as travelling down a long hill at excessive speed or with an overloaded vehicle, brake fade can become so severe and result in such a significant loss of brake force that you may be unable to slow or stop your vehicle.

Full brake capacity is not often needed during normal conditions. However, for safety, the full capacity of the brake system must always be available.

The brake force produced at a wheel drops significantly when the stroke of its brake chamber pushrod becomes excessive. When pushrod stroke becomes excessive, the vehicle loses some of its ability to stop. It is unlikely that you will notice a small loss of braking ability during normal driving. It may only become evident when higher demands are placed on the brakes such as heavier loads, higher speeds, long downhill grades or emergency stops.

When brake chamber pushrod stroke exceeds the adjustment limit, braking ability can be reduced so much that the brakes may not stop or hold the vehicle. Brakes must be kept properly adjusted to ensure each chamber pushrod stroke is within its adjustment limit.

Remember: Proper brake adjustment ensures that the brake chamber always produces the necessary force. When a brake is out of adjustment – when pushrod stroke exceeds the adjustment limit – braking ability is reduced.

Brakes that are out of adjustment cannot be detected except by a reliable inspection method.

When a wheel locks and a tire skids, a vehicle loses steering control and directional stability. Under certain driving conditions, you may find it difficult to get the brake force you want without causing one or more of the wheels to lock. Anti-lock braking systems, which are also called ABS, are designed to sense the speed of the wheels on a vehicle. An abnormal drop in wheel speed, which indicates potential wheel lock, causes the brake force to be reduced to that wheel. This is how the anti-lock braking system prevents tire skid and the accompanying loss of steering control. This improves vehicle safety during heavy brake use or when braking with poor traction.

Although anti-lock braking systems help to prevent wheel lock, you should not expect the stopping distance for your vehicle to be shortened. Under normal driving conditions on clean dry roads, you will notice no difference between vehicles with anti-lock braking and those without it.

Vehicles with anti-lock braking systems use warning indicator lights or malfunction lamps to indicate the status of the system and warn of malfunctions. These indicator lights are mounted on the dashboard or driver console. On trailers, the indicators are usually mounted in locations that make them visible in your rear-view mirror. You should be familiar with the location of anti-lock braking system indicators on your vehicle and how they work.

It is Important to note that if an anti-lock braking system malfunction occurs, regular brake function is still available.

An Australian made and owned manufacturer, AutoTest Products, is taking an innovative approach to testing equipment to ensure a brake’s capabilities and operating performance are factored into the safety of a vehicle.

AutoTest® provides a range of state-of-the-art automotive testing and diagnostic products, designed to improve the accuracy of the test results used to meet safety regulations. AutoTest products will also help generate business for workshops with or without Licensed Vehicle Testers (LVT) status.

AutoTest® offers product lines to cover all corners of the brake triangle; brake friction material, Brake Fluid, and suspension.

AutoTest® supplies workshops, regulatory authorities, and service testing stations across the world, including Australia, New Zealand, USA, UK, South Africa, Malaysia, Holland, France, and Germany, with products from the AutoStop range. AutoStop Maxi brake meter is used by over 3000 workshops in New South Wales alone!

AutoStop® Heavy is a portable, battery-powered, in-vehicle brake performance tester that measures average and maximum acceleration, stopping distance, test speed, and pedal-force required to stop a vehicle.

With built in GPS, it has everything to evaluate brake performance in a quick reliable manner, and prints an accurate test report that complies with International Standards. An efficient diagnostic and compliance tool, designed to test service and emergency brakes of heavy and slow- moving vehicles, off-road vehicles, and even forklifts used in the transport and mining industries. It complies with all the current regulations including the most recent amendment to ISO 3450.

ADMM May 2021 Article: Brake safety, brake systems as well as the brake testing regulations and its importance in all vehicles, explained.

AAAA June 2021 Article: Braking performance is critical in the avoidance of accidents and almost every single accident involves the application of the vehicle brakes.

Keep your workshop and equipment updated!

Subscribe to our newsletter for exclusive sales, discounts, and the latest news.

Sign up today!